Fixture setup-Time Shortened by Half

Fixture Setup-Time was Shortened by half with the tool-less Changeover

Quarter-Turn are used for

Our mold production team manufactures cases and covers for our products using advanced injection molding machines. After molding, a take-out robot pulls the products from the machine, and they are transported for further processing. The resin burr on the back of each injection-molded product is cut using a nipper.

We operate 15 injection molding machines in our plant:

- 4 dedicated machines

- 11 general-purpose machines for producing a wide variety of products in small quantities

For the general-purpose machines, frequent mold changes are required depending on the product being formed. Some machines undergo mold changes more than 50 times a month. Additionally, because the position of the resin burr varies by product, the nipper and its position must be adjusted during each mold change, impacting fixture setup time.

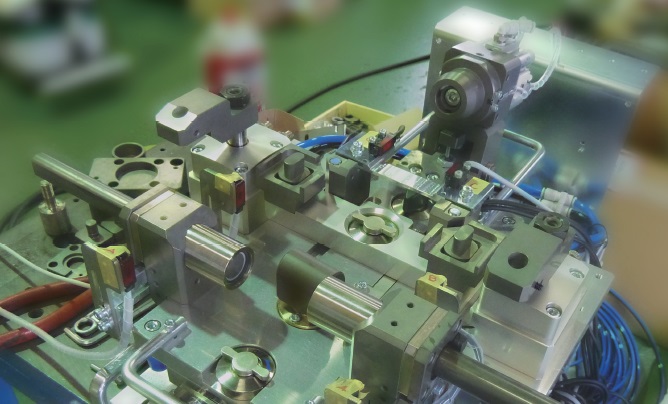

Previously, we used general-purpose nipper units, which required significant time to loosen screws, change nippers, and adjust their positions. To improve fixture setup time, we now use nipper units (highlighted in blue in fig.1) dedicated to each product. These units are exchanged with every mold change, and SpanClamps’ QUARTER-TURN CLAMPS (highlighted in red in fig.1) are used for precise positioning and clamping of the nipper units.

References Used

SpanClamp Quarter-Turn SCQT-P

Plastic Wing Head: SCQT0614-P

Receptacle: SCQTRBI12

Results

What are the added values of SpanClamps quarter-turn?

With SpanClamps quarter-turn, clamp units can now be replaced with a single press of a button. This innovation reduces fixture setup time to just 1 minute, compared to the previous 15–30 minutes.

Another advantage is the simplicity of operation: unit changes can be performed easily by anyone. Previously, clamp adjustments required expertise, limiting changes to trained personnel. Now, anyone can handle the process by turning the knob 90 degrees to the ON position and connecting two air tubes to the joints.

Modern output robots are slaved, meaning only an NC program change is needed for product changes during molding. Furthermore, the quarter-turn system has significantly shortened the installation time for dump units. With power-assisted extraction robots and the quarter-turn mechanism, machine downtime during mold changes was drastically reduced, leading to improved productivity and optimized fixture setup time.

Challenge

What is the most important point in improving your production system?

"Reduce installation time" is at the core of every challenge we face.

In the past, burr cutting was done manually and later outsourced to a subcontractor. To improve productivity, we automated the burr-cutting process using cutting pliers. However, fixture setup time was still prolonged because we had to loosen screws to change or adjust the clamp position during every mold change. This inefficiency arose because the units were designed as versatile tools for all products.

In mass production, where molds remain in place for extended periods, this was not an issue. However, with many of our products manufactured in small quantities, machine downtime increased significantly due to lengthy mold installation times.

To address this, we developed dedicated gripper units for each product, allowing entire units to be swapped during mold changes. Additionally, we integrated SpanClamps quarter-turn mechanisms, which tighten units faster than screws, drastically reducing fixture setup time and boosting overall productivity.

How to Select the SpanClamps Quarter-Turn?

How did you find the quarter-turns to tighten your clamp units?

When we consulted with Anemo Engineering, a fast-moving solutions company for the industry, they introduced us to the SpanClamps range.

In the catalog, we discovered the "quarter-turn" range, which offers various quick-fix solutions to optimize fixture setup time. Among the options, we selected the product that best matched our specific requirements and intended use.

Criteria

Using a SpanClamp Quarter-Turn

Why did you choose quarter-turns for your clamp units?

We specifically wanted a solution that allowed us "to tighten the parts in a single operation." Quarter-turns proved ideal, as they can secure the parts with a simple 90-degree turn of the button. Additionally, the clamping force of 90 N provided sufficient safety to hold the units firmly in place.

Another critical factor was the height of the fasteners. Since operators need to hold the clamp unit during the exchange operation, reducing weight was essential. To achieve this, we minimized the thickness of the unit plates and opted for low-profile mountings compatible with thin plates, optimizing fixture setup time.

Lastly, we prioritized the ability to visibly confirm the clamping and unclamping states of the unit. The button’s position clearly indicates whether the unit is securely fixed or not. This visual check allows operators to ensure proper locking instantly, and others can verify it remotely, reducing the chance of errors during the process.

How do you rate the ease of use of the quarter-turn?

The downtime of our machines has been significantly reduced thanks to the instant switching of gripper units, improving fixture setup time. Six of our 11 general-purpose machines now use quarter-turns, achieving a high utilization rate. (The remaining five machines are used for products with different shapes of strawberries.)

We are also very satisfied with the "visualization" of operations. For example, in our factory, "a vertical button indicates locked, while a horizontal button indicates unlocked." This simple visual cue enables not only the operator but also any third person to quickly verify whether a unit is secured.

The easily recognizable locked and unlocked states have enhanced safety across our factory. While human error, such as forgetting to lock a device, cannot be entirely eliminated, adopting this straightforward verification system has minimized risks and ensured safer, more efficient operations.